- +91 8076217931

- officialsteelmart@gmail.com

- KH. No. 100/17/1, Mundka Industrial Area, Pole No. MDK Near Sentek Factory, New Delhi-110041

Steel Supplier

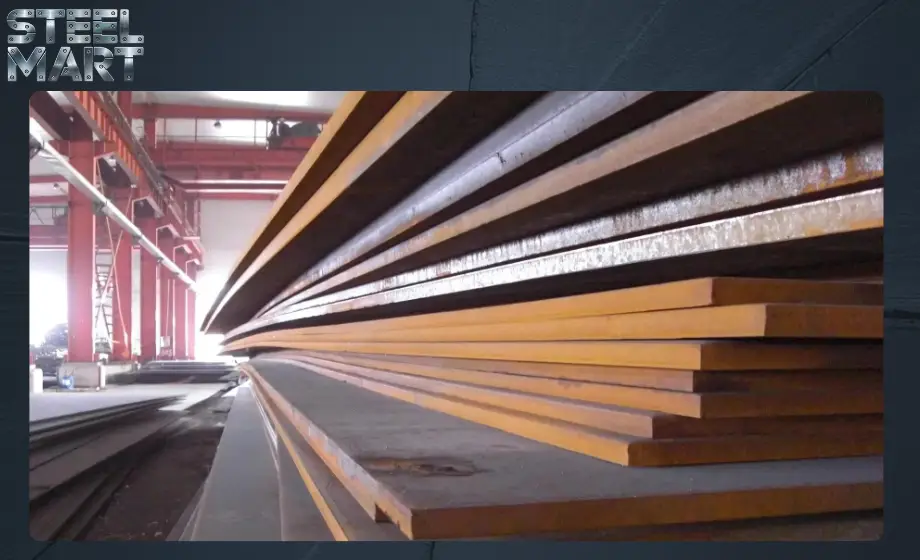

Abrasion Resistant Plate – Rock Star 400/450/500

Typical Chemical Composition (%)

| Grade | C | Mn | Si | Cr | Mo | B |

|---|---|---|---|---|---|---|

| Rock Star 400 | ≤0.30 | ≤1.70 | ≤0.70 | ≤1.50 | ≤0.60 | ≤0.005 |

| Rock Star 450 | ≤0.30 | ≤1.70 | ≤0.70 | ≤1.80 | ≤0.60 | ≤0.005 |

| Rock Star 500 | ≤0.35 | ≤1.70 | ≤0.70 | ≤2.00 | ≤0.60 | ≤0.005 |

Abrasion Resistant Plates – Rock Star 400 / 450 / 500

Premium-grade abrasion-resistant (AR) steel plates, Rock Star 400, 450, and 500 are designed to function remarkably well in settings where durability and high wear resistance are essential. In order to provide exceptional mechanical strength, excellent surface toughness, and prolonged wear life under the most severe situations, these plates are made utilizing sophisticated metallurgical methods. Regardless of your industry—mining, earthmoving, building, recycling, cement, or quarrying—Rock Star AR plates provide the durability and functionality you require to lower maintenance expenses and downtime.Available Grades & Properties:

| Grade | Typical Hardness (HBW) | Highlights | Primary Uses |

|---|---|---|---|

| Rock Star 400 | ~400 HB | Excellent balance of wear resistance and formability | Liners, hoppers, earthmoving equipment |

| Rock Star 450 | ~450 HB | Increased hardness and impact resistance | Dump truck bodies, buckets, feeders |

| Rock Star 500 | ~500 HB | Maximum hardness for extreme wear conditions | Shredder parts, crusher liners, cutting edges |

Key Features:

-

Outstanding abrasion and wear resistance

-

Uniform hardness distribution throughout the thickness

-

High impact toughness, even in low temperatures

-

Enhanced machinability, weldability, and cold formability

-

Long service life, reducing repair and replacement frequency

Mechanical Properties:

-

Hardness Range:

-

Rock Star 400: 360–440 HBW

-

Rock Star 450: 420–480 HBW

-

Rock Star 500: 470–540 HBW

-

-

Yield Strength: Up to 1400 MPa

-

Tensile Strength: Up to 1800 MPa

-

Elongation: 8–14%

-

Density: ~7.85 g/cm³

Fabrication & Workability:

-

Welding: Good weldability with proper technique and preheat (depending on thickness)

-

Forming: Suitable for cold bending; best formability in 400 & 450 grades

-

Cutting: Can be cut via oxy-fuel, plasma, laser, or abrasive water jet

Sizes Available:

-

Thickness: 6 mm to 100 mm

-

Width: Up to 2500 mm

-

Length: Up to 12000 mm

-

Custom-cut profiles and drilled plates available upon request.

Equivalent Grades:

| Rock Star Grade | Comparable Plates |

|---|---|

| Rock Star 400 | Hardox 400, Abrex 400, NM 400 |

| Rock Star 450 | Hardox 450, Abrex 450, Xar 450 |

| Rock Star 500 | Hardox 500, Abrex 500, Xar 500, NM 500 |

Typical Applications:

-

Mining & Earthmoving: Liner plates, dump truck bodies, dragline buckets

-

Construction: Excavator arms, dozer blades, rock buckets

-

Cement & Quarrying: Hopper liners, clinker handling, transfer chutes

-

Recycling & Waste Handling: Shredders, crushers, screen plates

Nationwide Supply Across India:

We deliver Rock Star abrasion-resistant plates across all industrial zones in India, including:

-

Uttar Pradesh – Lucknow, Kanpur, Noida, Varanasi, Meerut

-

Rajasthan – Jaipur, Udaipur, Kota, Jodhpur, Bhiwadi

-

Haryana – Faridabad, Gurugram, Hisar, Ambala, Panipat

-

Gujarat, Maharashtra, Chhattisgarh, Tamil Nadu, West Bengal, Telangana – and more

Why choose Steel Mart as a C45 Carbon Steel Supplier?

- Certified Premium Quality: They provide high-quality, often ISI-certified C45 Carbon Steel Supplier with complete documentation like Mill Test Certificates (MTCs), ensuring guaranteed chemical composition and mechanical properties.

- Value-Added Processing: They offer essential services like cut-to-size options and processing (machining, grinding) tailored to your exact specifications, which minimizes your processing time and scrap.

- Reliable Supply & Logistics: They maintain a ready and extensive stock of C45 steel in various forms and boast a strong supply chain network for fast, on-time delivery.

- Industry Experience & Trust: With a long-standing legacy (often cited as 50+ years), they bring deep technical expertise and a trusted reputation for reliability and honest business practices.

- Technical Support & Guidance: Their team provides valuable technical advice and consultation on material selection, heat treatment, and fabrication, acting as a supportive partner for your project.