- +91 8076217931

- officialsteelmart@gmail.com

- KH. No. 100/17/1, Mundka Industrial Area, Pole No. MDK Near Sentek Factory, New Delhi-110041

Steel Supplier

Plastic Mold Steel -P20+Ni (1.2738)

Chemical Composition (%):

| Element | Composition (%) |

|---|---|

| C (Carbon) | 0.35–0.45 |

| Mn (Manganese) | 1.30–1.60 |

| Si (Silicon) | 0.20–0.40 |

| Cr (Chromium) | 1.80–2.10 |

| Mo (Molybdenum) | 0.15–0.25 |

| Ni (Nickel) | 0.90–1.20 |

| P (Phosphorus) (Max) | ≤0.030 |

| S (Sulfur) (Max) | ≤0.030 |

Plastic Mold Steel – Grade 1.2738 / P20+Ni / AISI P20+Ni

Overview:

Grade 1.2738 is a premium plastic mold steel designed specifically for large, high-performance plastic injection molds. It is equivalent to AISI P20+Ni, offering improved toughness, uniform hardness, and excellent machinability. The addition of Nickel, Chromium, and Molybdenum enhances its hardness, toughness, and dimensional stability, making it a preferred choice in the plastic mold industry.

This steel is supplied in a pre-hardened, quenched and tempered condition, typically at a hardness of 280–320 BHN (32–36 HRC), ready for immediate use without the need for further heat treatment.

Key Characteristics:

-

Uniform hardness across large cross-sections

-

Good machinability and polishability

-

Suitable for texturing and surface finishing

-

Moderate corrosion resistance

-

Can be nitrided and chrome-plated

-

Fair weldability with proper preheating and post-weld tempering

Physical & Mechanical Properties:

| Property | Value |

|---|---|

| Modulus of Elasticity | 205 × 10³ N/mm² |

| Density | 7.80 g/cm³ |

| Thermal Conductivity (100 °C) | 33.5 W/m·K |

| Average Thermal Conductivity | 29.0 W/m·K |

| Specific Heat Capacity | 0.46 J/g·K |

| Tensile Strength | ≈ 1080 N/mm² |

| Delivered Hardness | 32–36 HRC |

| High Hardness Variant | Up to 38–40 HRC |

Heat Treatment (Reference Only):

Note: Grade 1.2738 is usually delivered in a pre-hardened condition. Additional heat treatment is not required unless specified.

-

Forging Temperature: 1050–850 °C

-

Soft Annealing: 710–740 °C

-

Quenching: 840–870 °C (if required)

-

Tempering (Post-Weld or Stress Relief): As per application

Equivalent Grades:

| Standard | Grade |

|---|---|

| DIN | 1.2738 |

| AISI | P20+Ni |

| UNS | 40CrMnNiMo8-6-4 |

Applications:

-

Large and medium-sized plastic injection molds

-

Die-casting dies and compression molds

-

Mold bases, bolster plates, and press holders

-

Dies for household product manufacturing

-

High-finish plastic molding components

-

Forging dies and drop hammer blocks

-

Hydroforming tools and mold inserts

-

Chrome-plated or nitrided molds for longer tool life

Suitable for tools requiring high polishability, wear resistance, and excellent dimensional stability across heavy-duty, repetitive operations.

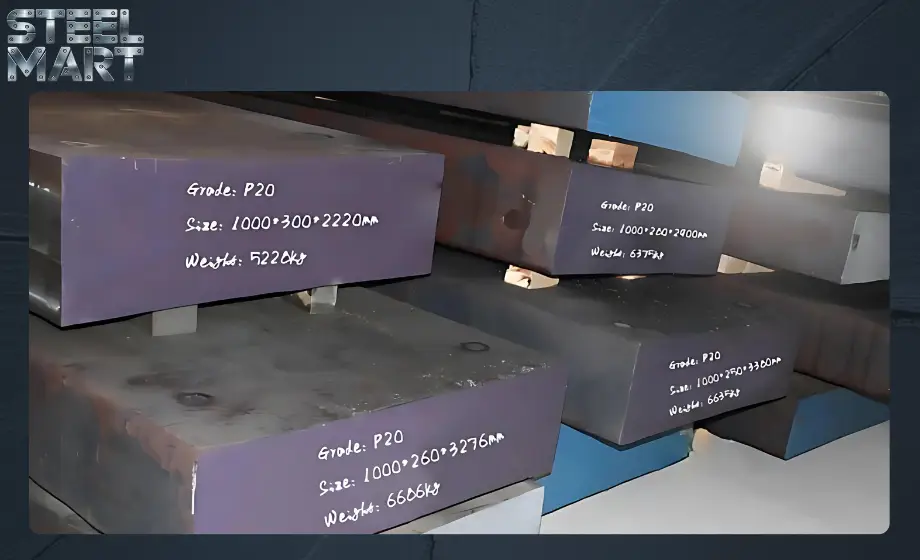

Available Forms:

-

Round Bars

-

Flat Bars

-

Blocks

-

Plates

-

Custom Sizes as per Drawing

Other Grades Available:

C45, EN8, EN9, EN19, EN24, EN31, EN36C, EN41B, EN47, EN353, IS2062, 42CrMo4, HCHCR, OHNS, D2, D3, H11, H13, M2, M35, M42, M48, 1.2714, SKD-11, P20, P20+S, P20+Ni, P20+Ni+HH, SAE 4140, SAE 4340, SAE 8620, 16MnCr5, 20MnCr5, C35, C40, C50, C60, CK45, 40C8, 45C8, 55C8, C55Mn75, SAE 52100, S40C, S355J2G3.

We Deliver Across PAN India

Uttar Pradesh:

Kanpur, Lucknow, Noida, Ghaziabad, Agra, Meerut, Varanasi, Gorakhpur, Bareilly, Moradabad, Aligarh, Saharanpur, Prayagraj, Jhansi, Muzaffarnagar, Mathura, Ayodhya, and many more.

Rajasthan:

Jaipur, Jodhpur, Kota, Udaipur, Bhiwadi, Ajmer, Bikaner, Bhilwara, Alwar, Sri Ganganagar, Sikar, Hanumangarh, Bharatpur, Dungarpur, Churu, and other cities.

Haryana:

Gurgaon, Faridabad, Panipat, Hisar, Karnal, Rohtak, Sonipat, Yamunanagar, Ambala, Rewari, Bahadurgarh, Sirsa, Bhiwani, Kaithal, and more.

Why choose Steel Mart as a C45 Carbon Steel Supplier?

- Certified Premium Quality: They provide high-quality, often ISI-certified C45 Carbon Steel Supplier with complete documentation like Mill Test Certificates (MTCs), ensuring guaranteed chemical composition and mechanical properties.

- Value-Added Processing: They offer essential services like cut-to-size options and processing (machining, grinding) tailored to your exact specifications, which minimizes your processing time and scrap.

- Reliable Supply & Logistics: They maintain a ready and extensive stock of C45 steel in various forms and boast a strong supply chain network for fast, on-time delivery.

- Industry Experience & Trust: With a long-standing legacy (often cited as 50+ years), they bring deep technical expertise and a trusted reputation for reliability and honest business practices.

- Technical Support & Guidance: Their team provides valuable technical advice and consultation on material selection, heat treatment, and fabrication, acting as a supportive partner for your project.